Products

Related

Home >> Products >> Titanium titanium electrode (anode) >> Ruthenium - based titanium electrode

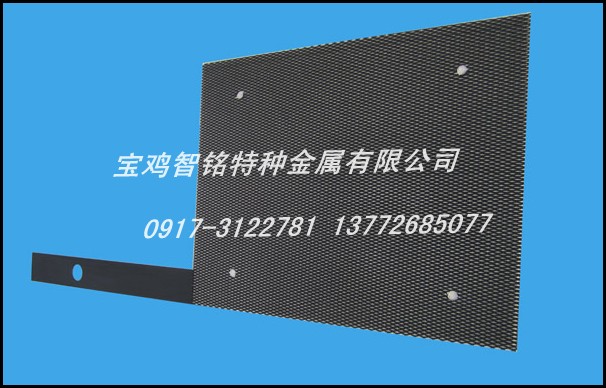

Wastewater treatment Titanium anode |

Wastewater treatment of titanium titanium anode electrode Wastewater treatment technology including sedimentation, filtration, flocculation, biodegradation, a variety of means such as electrolytic oxidation. Electrolytic process wastewater treatment, passes current electrode not only plays a role, but also plays a role of catalytic oxidation of organic matter degradation, and will not cause secondary pollution, known as green water treatment technology. For cannot adopt biological degradation of wastewater treatment, using electrolytic oxidation method often has a significant effect, so the electrolysis of water treatment technology has become a research hotspot, water treatment technology has been more and more widely used. Electrolysis of water treatment technology is the basic principle of pollutants occur on the electrode electrochemical reaction directly or indirectly electrochemical conversion, namely direct or indirect electrolysis of electrolysis. (1) direct electrolysis Electrolysis is refers to the contaminant on the electrode directly directly by oxidation or reduction and removal from the wastewater. Direct electrolysis process can be divided into the anode and the cathode process. Anodic process is the pollutants in the surface of the anode oxidation and into less harmful substances or easily biodegradable material, inorganic, organic matter, even so as to achieve the aim of cut, to remove pollutants. Cathode process is to remove pollutants reduction at the cathode surface, mainly for the reductive dehalogenation of halogenated hydrocarbons and heavy metals recycling. (2) indirect electrolysis Indirect electrolysis is refers to the use of electrochemical REDOX material as a reactant or catalyst, the transformation of pollutants into less toxic substances. Indirect electrolysis can be divided into reversible and irreversible process. Reversible electrochemical oxidation (medium) refers to the oxidation and the original electrochemical regeneration and can be recycled in the process of electrolysis. Refers to the use of the irreversible process is not reversible electrochemical reaction substances, such as has the strong oxidizing chlorate, hypochlorous acid salt, H2O2 and O3 process of oxidation of organic compounds, such as electrochemical reaction can also be used to produce strong oxidizing intermediates, including solvated electron,, HO, such as O2 - • HO2, free radicals. Electrolysis treatment new technology without adding chemical reagents, water device has small volume, covers an area of small, does not produce secondary pollution, has been used in hydrocarbon processing, alcohol, aldehyde, ether, phenol and other organic waste water pollution. Removal of COD depend mainly on the surface of the anode oxidation reaction, directly on the surface of the anode oxidation degradation of organic matter, organic matter in wastewater by electrochemical conversion, directly or indirectly into CO2 and water. Potential anode voltage must be higher than that of organic matter decomposition, so on the anodic oxidation of organic matter and oxygen two competitive reactions. The shape of the anode plate, tube type, mesh type, and other forms for users to choose, the quality is reliable. The titanium substrate can be repeated use. Typical applications: Of printing and dyeing wastewater treatment, waste exudate, wastewater treatment, oily wastewater treatment, the cyanide waste water treatment, electrolysis method in wastewater recycling metal, hospital wastewater treatment, food and beverage wastewater treatment, etc. Tech support: ZhiMing titanium anode and electrode (86 13772685077) |